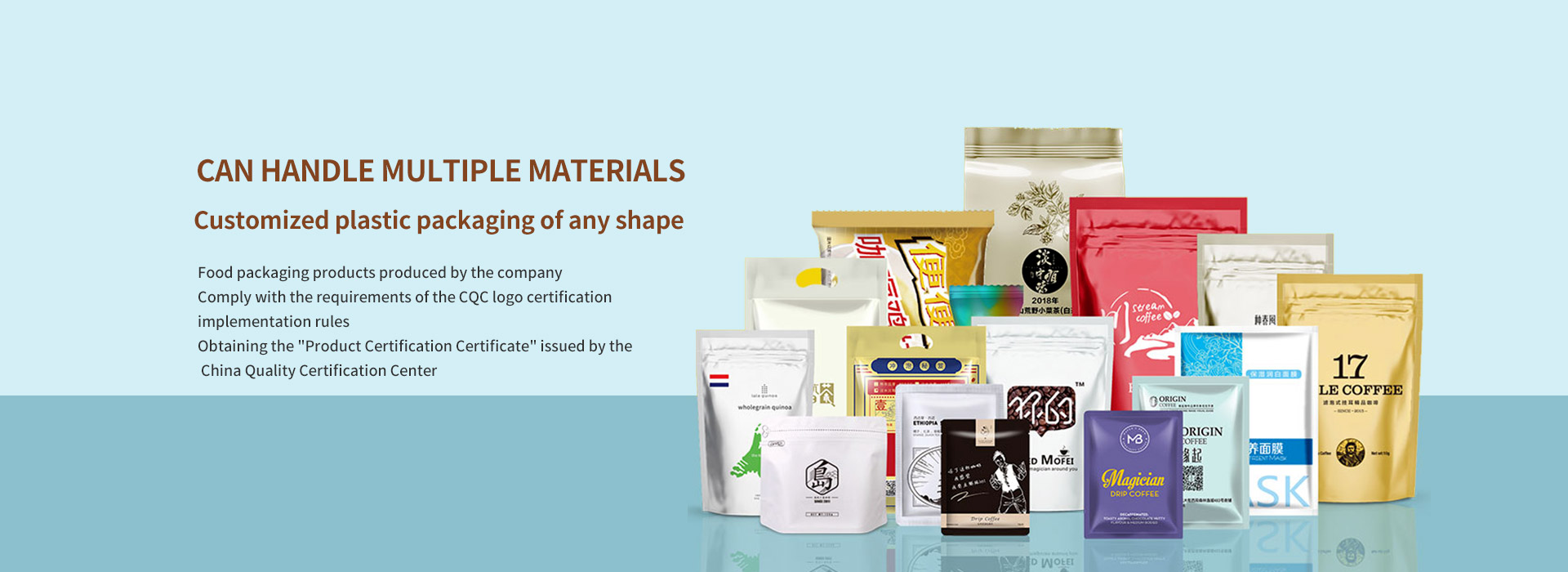

Food-grade packaging bags to meet the needs of food protecti

Food packaging bags are generally divided into: ordinary food packaging bags, vacuum food packaging bags, inflatable food packaging bags, poached food packaging bags, retort food packaging bags and functional food packaging bags. There are also many types of food packaging bags: PE bags, aluminum foil bags, composite bags, and nylon bags are more common.

The vacuum bag is to take out all the air in the package and keep the bag under high decompression condition. The air is rare, which is equivalent to the low oxygen effect, so that the microorganisms have no living conditions, so as to achieve the purpose of fresh food and no disease rot.

The food foil bag is made of aluminum foil bag after dry compounding with aluminum and other high barrier materials according to the unique properties of aluminum. The aluminum foil bag has good functions of moisture resistance, barrier, light protection, penetration resistance and appearance.

Food-grade composite bags are moisture-proof, cold-resistant, and low-temperature heat-sealed; they are used in instant noodles, snacks, frozen snacks, and powder packaging.

Food-grade bags must meet the protection needs of all aspects of food:

1. Food packaging requirements can block water vapor, gas, grease and organic solvents;

2. According to the special requirements of actual production, increase the functions of anti-rust, anti-corrosion and anti-electromagnetic radiation;

3, to ensure food safety and pollution without extending the shelf life of food.

The main materials and auxiliary materials used in food-grade packaging should not contain substances that are harmful to the human body, or the content is within the range allowed by national standards.

Due to the special nature of food-grade packaging, products can only be passed and put into the market if they are strictly in accordance with the specifications of production.

All the inner packaging bags that come into contact with food are strictly in accordance with the production process of food-grade packaging bags, which are not only safe and hygienic, but also ensure the delicious original flavor.

In the case of non-food grade packaging bags, the main difference in material composition is the use of additives. If an opening agent is added to the material, it cannot be used for food packaging.

So how do we distinguish whether the bag is non-food grade or food grade?

When we get the bag, we first observe that the new material has no peculiar smell, good hand feeling, uniform texture and bright color. Only these are the food-grade environmental protection bags that are safe and hygienic.

Qingdao Zhongtuo Plastic Industry Co., Ltd. specializes in producing food packaging bags for 18 years, with exquisite printing, high quality and low price, fast delivery, and sincerely look forward to cooperating with you! 24-hour service hotline: +86 15020031364