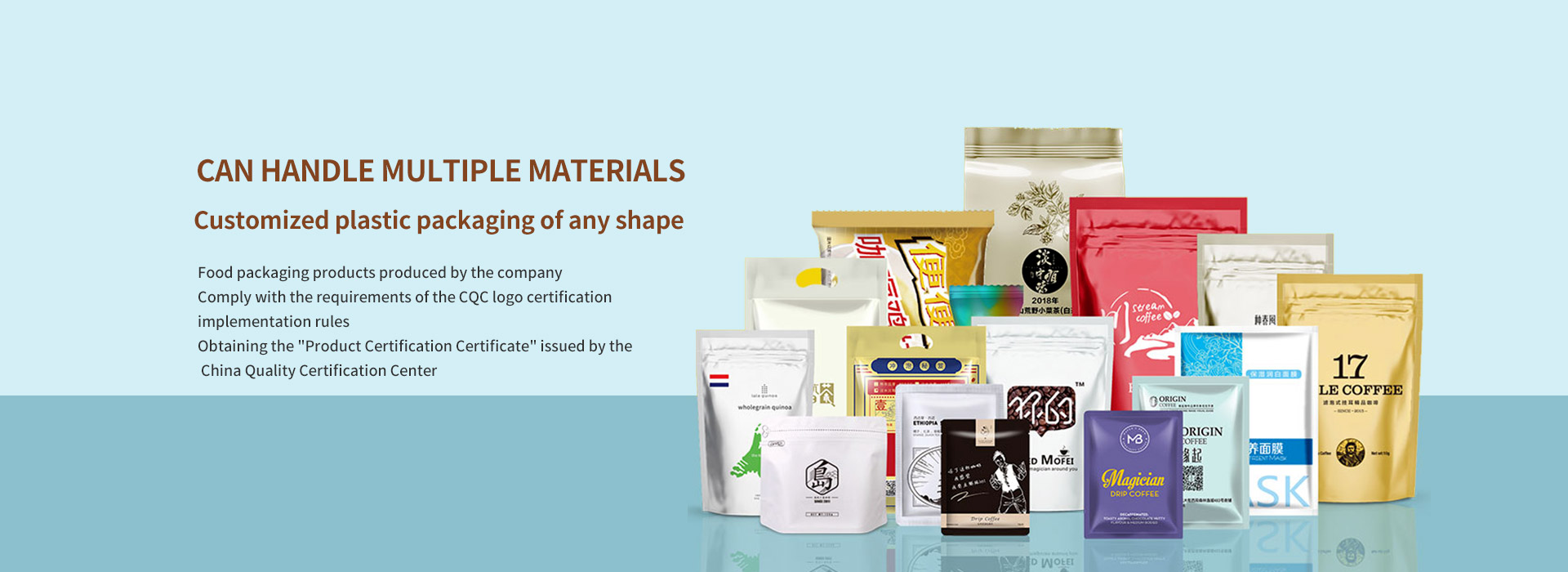

What are the ingredients of the vacuum bag?

The vacuum packaging bag is to pack the air out of the bag to form an internal vacuum, and the function of the vacuum packaging bag is to prevent air circulation, so as to ensure that the outside air does not mix into the bag, thereby achieving the product. Better preservation, and vacuum packaging bags also have their classification. Do you know what kind of material is vacuum packaging bag made of?

What are the ingredients of the vacuum bag?

The material properties of vacuum bags directly affect the shelf life of food and the impact of its taste. Therefore, when choosing packaging, you should not only look at the packaged products but also the packaging materials. Vacuum bags are more than one material, different materials have different properties, and vacuum packaging bags are classified into the following categories:

1, PE material, general PE material is suitable for use in low temperature environment, so it is suitable for some seafood and other fresh products.

2, RCPP material, suitable for cooking in high temperature environment.

3, PA material, generally in the vacuum packaging bag will be added AP material, the main purpose is to increase physical strength and puncture resistance.

4, AL aluminum foil, this material is mainly to increase the barrier properties and shading, generally included in the vacuum packaging bag.

5, water resistant PVA, this material is to increase the barrier properties, forming a high barrier coating.

6, PET material, with excellent physical and mechanical properties, creep resistance, fatigue resistance, friction resistance, deformation is not easy.

However, according to the needs of use, our vacuum packaging bags are combined using these materials, and the combinations are as follows:

1, PA + PE and PA + RCPP, resistant to low temperature puncture and high temperature puncture.

2, PET + PE and PET + RCPP, low temperature friction and high temperature friction.

There are also two or more materials

3, PET + PA + PE

4, PA + AL + RCPP

5, PET + PA + AL + RCPP

6, PET + PA + PE